Chronicle

Chronicle

Our Company History

A Chronicle Through Time and Space

Chronicle

Chronicle

1940s

2

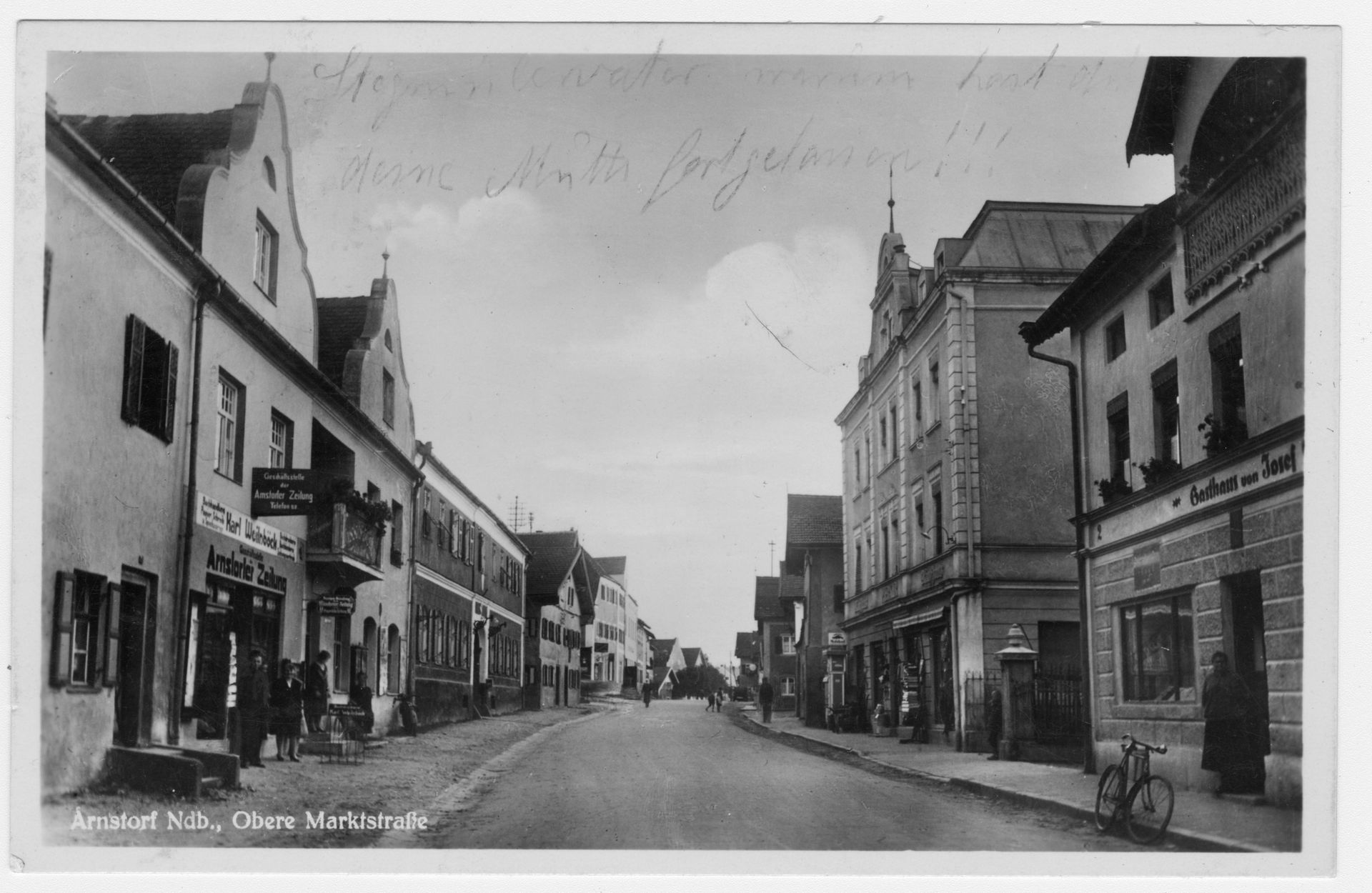

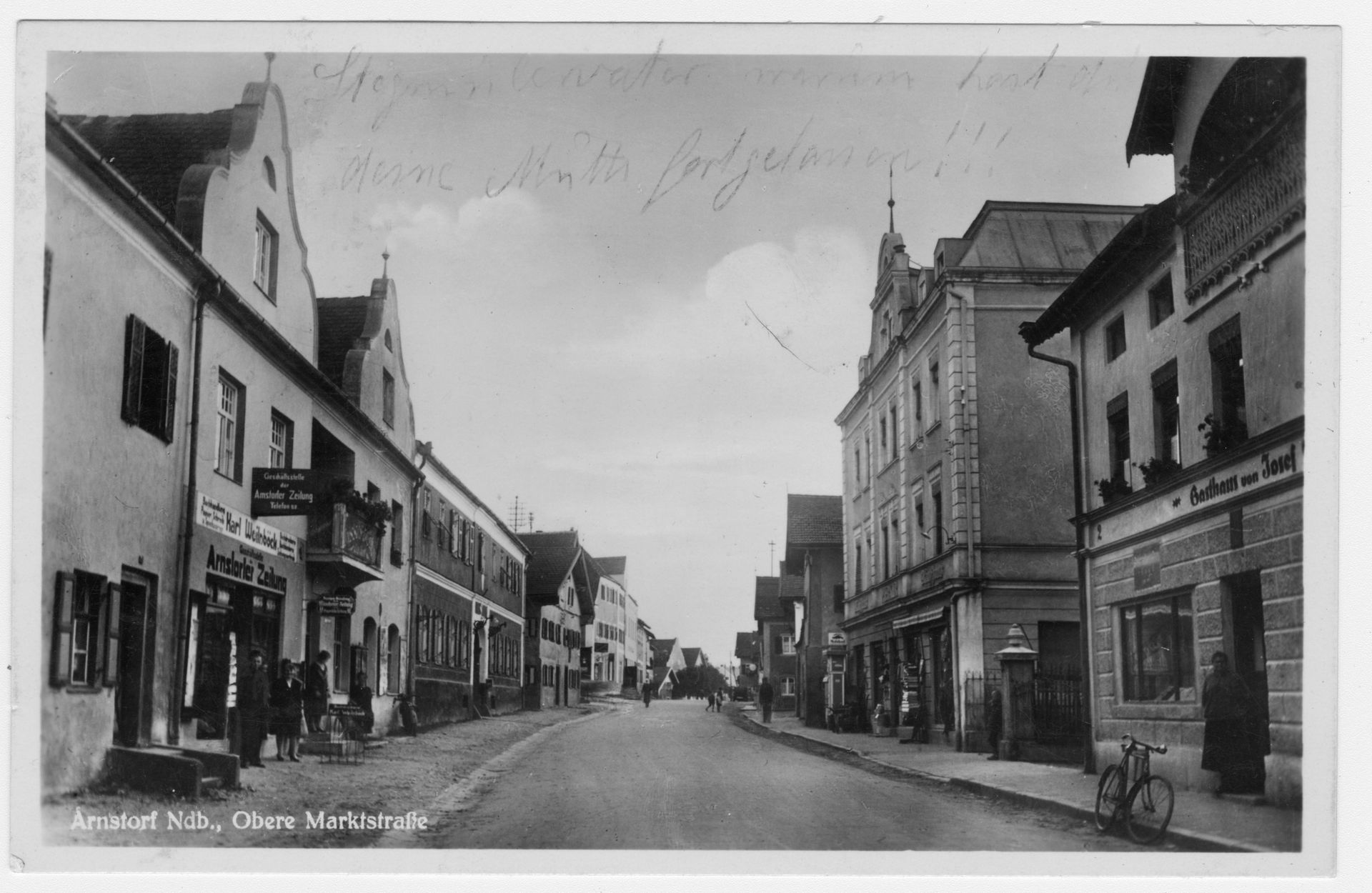

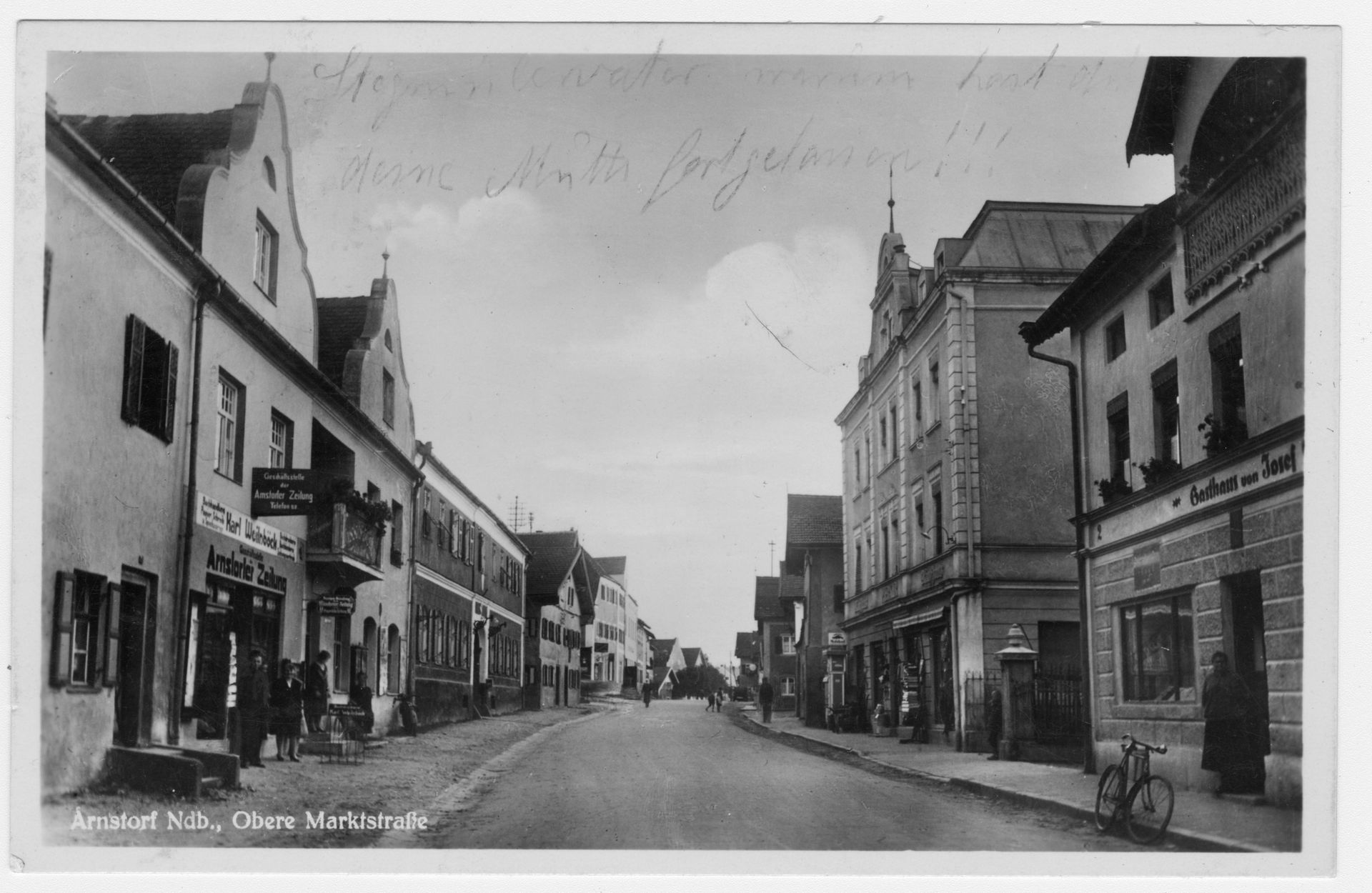

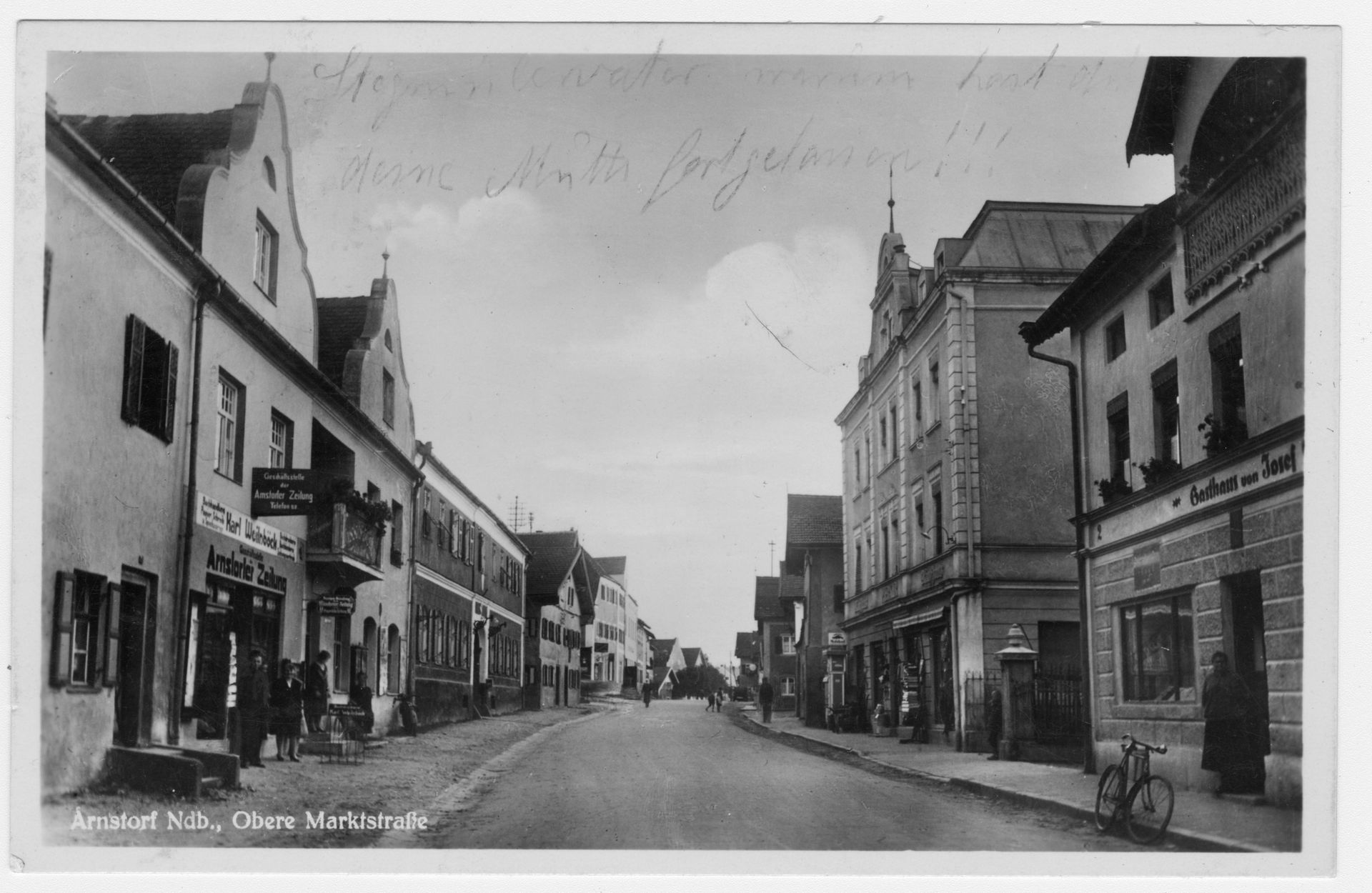

Hans Lindner

Hans Lindner is born in Arnstorf, the son of innkeepers Hans and Therese Lindner.

1940s

Chronicle

1950s

2

Entrepreneurial Roots in the Family

After primary school, Hans Lindner transfers to the humanist grammar school at Kloster Metten. He spends the holidays at the family-owned inn in Arnstorf, run mainly by his mother, where he gains his first professional experience. At the same time, his father, Hans Lindner Sr., continues a small timber business after returning from captivity as a prisoner of war. The entrepreneurial spirit of his parents leaves a lasting impression on Hans, who later recalls that he “thought more about marketing agricultural products and building houses than about the conjugation of Latin verbs.”

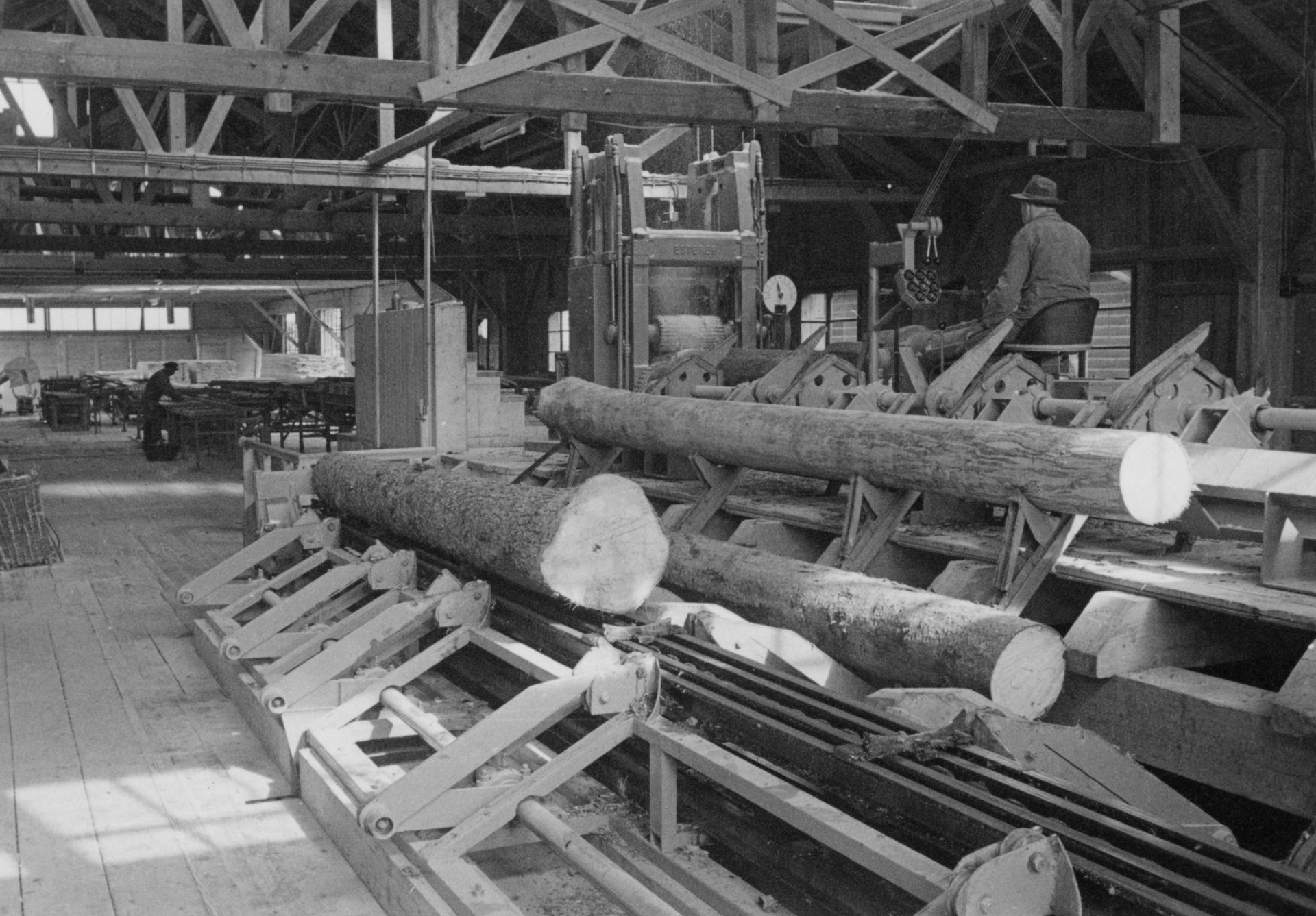

Apprenticeship at the Sawmill

At the age of 17, Hans Lindner begins a commercial apprenticeship at the Wimmer sawmill in nearby Pfarrkirchen. Despite his youth, the owner soon entrusts him with responsible tasks, including operating a long-wood vehicle.

1950s

Chronicle

1960s

3

His Dream: Prefabricated House Construction

At 22, Hans Lindner graduates top of his class from the commercial programme at the State Engineering School for Timber Technology (now Rosenheim University of Applied Sciences). He dreams of travelling to Finland, the “land of prefabricated houses,” to gain experience before building prefabricated homes himself in Germany. But life takes a different path: after his mother falls seriously ill and passes away at a young age, he stays nearby and works as deputy operations manager at Isartaler-Holzhaus in Holzkirchen, near Munich.

The First Contract of Akustikbau Lindner GmbH

At the age of 24, Hans Lindner finally sets up his own company, Akustikbau Lindner GmbH. His first contract comes through Mr Schmid, a freelance representative of a building materials manufacturer: a suspended acoustic ceiling at the Agricultural Vocational School in Deggendorf. For the project, valued at 35,000 DM, the architect Rudel from Plattling had specified a modern building material for the acoustic ceiling. The wooden substructure was constructed in his father’s shed. Together with two unemployed carpenters from the Bavarian Forest, Hans – who worked on the scaffolding himself every day – installed the ceiling in just under six weeks, to the complete satisfaction of the client. He immediately recognises the potential of the interior construction market, and his original vision of building prefabricated houses takes a back seat.

First Major Projects in Bavaria

By 1968, Akustikbau Lindner secures its first larger-scale projects, including the University of Regensburg, Munich’s U-Bahn stations, and the Stachus building complex.

1960s

Chronicle

1970s

4

The First Production Facility in Arnstorf

Next came the construction of a joinery workshop as the company’s first production facility. Ceiling and partition systems manufactured in-house were the first products. The joinery still forms the foundation of Lindner’s Object Design department today.

During Germany’s period of full employment, Lindner grew faster than the labour market could keep up with, leaving vacancies unfilled. Hans Lindner and his early colleagues decided to recruit 100 Turkish employees. They helped to build the company further and soon took on leadership roles in the on-site project teams. Most of these colleagues remained with Lindner until their well-earned retirement.

Building for the Olympics

For the 1972 Munich Olympic Games, Lindner was commissioned to fit out the student dormitories, the equestrian facilities, and the Olympic Village.

Growth: 400 Employees

The company continued to expand: Lindner Akustikbau GmbH now employed nearly 400 people.

The First Holiday Home for Employees

In 1974, Lindner built the first holiday home for employees directly on the Costa Blanca in Spain. As the workforce continued to grow, it became necessary to provide additional holiday options in other regions. Further holiday homes with multiple units were established, available free of charge to employees and their families in Germany, South Tyrol, Austria, Ireland, Slovakia, and Croatia. Every year, more than 1,000 colleagues spend their holidays here with family and friends.

Lindner Becomes a Full-Service Provider

The company’s first major turnkey project was the University of Wuppertal. The substantial contract, valued at 22 million DM, required extraordinary effort to complete, yet the client was satisfied with the finished project.

Launch of the Monthly Employee Newsletter

The first edition of the employee newsletter, Lindner Intern, was published – written collaboratively by staff and management. To this day, every employee receives it monthly: from colleagues, for colleagues.

1970s

Chronicle

1980s

5

The Beginning of Lindner Insulation Technology

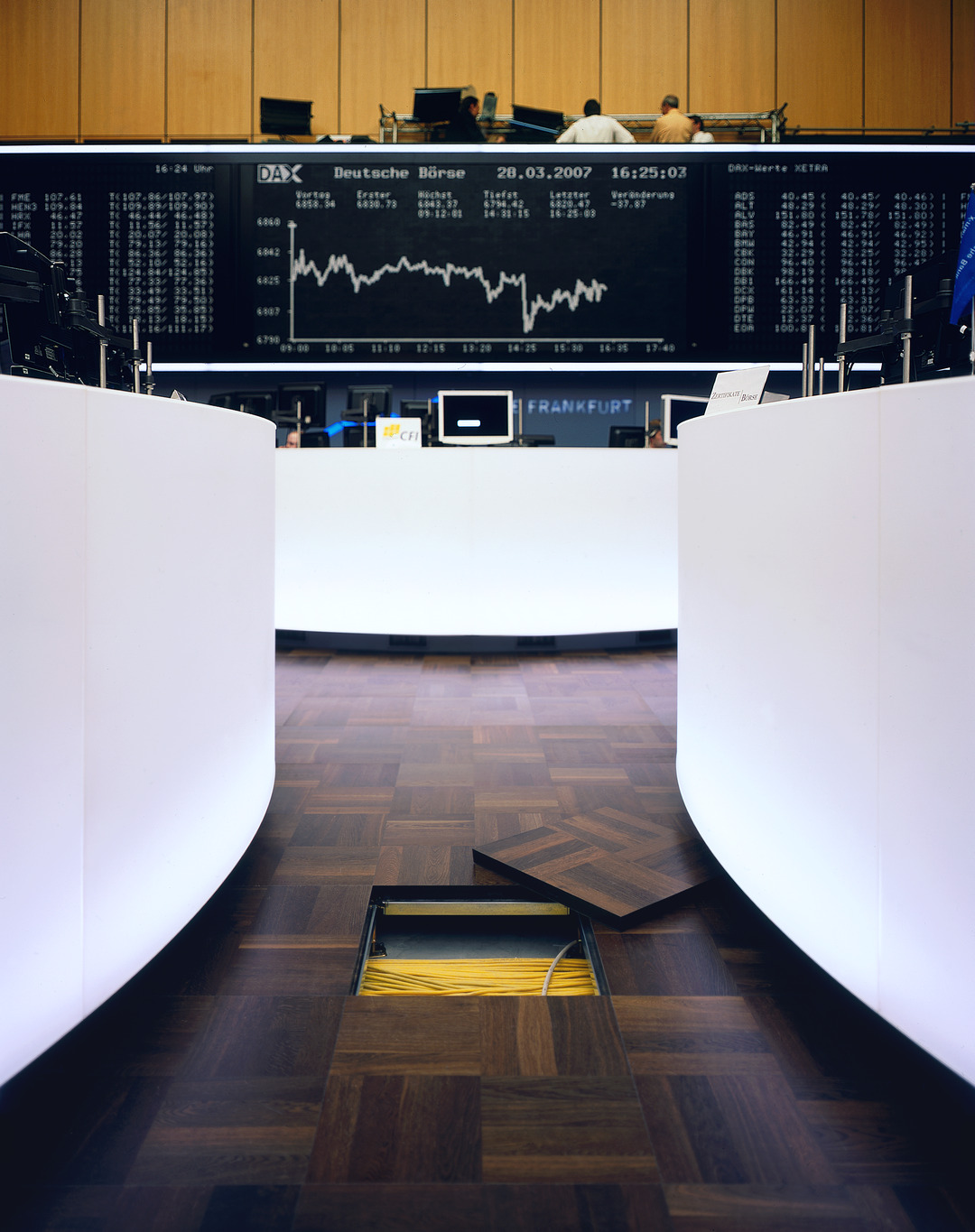

Hans Lindner acquires Jade Holzwerke in Wilhelmshaven. The takeover of this specialist in veneered panels paves the way for the contract to supply the wooden walls for Deutsche Bank in Frankfurt. Twenty-five years later, the two towers mark another milestone.

Alongside its core interior construction business, a second major division emerges: with the acquisition of the Röckelein craft business in Munich, Lindner Insulation Technology is launched. This business unit develops into a recognised specialist in insulation and environmental protection technology.

In 1982, the first international subsidiary is established in Baden near Vienna. After difficult initial years, Lindner Austria (together with the raised-floor company Goldbach) has grown into one of the Lindner Group’s most successful subsidiaries.

Reorganisation: Small Companies Within the Company

Following rapid growth during the first 19 years, structural challenges become apparent. To ensure continued success, Hans Lindner decides to restructure the organisation. For example, sales and project management are combined to improve customer service and quality – an approach that remains a successful model to this day.

Small internal profit centres encourage entrepreneurial thinking among employees. Since then, 15 percent of the company’s success has been shared with staff.

Lindner Produces Flooring Systems

Lindner begins manufacturing system floors. In a short time, our raised and hollow floors, alongside Lindner’s ceiling and wall systems, become the company’s third major construction division.

At the same time, Hans Lindner drives the company’s international expansion, targeting markets in Eastern Europe and the United Kingdom.

From Akustikbau Lindner GmbH to Lindner AG

The transformation into a public limited company, Lindner AG – Ceilings, Floors, Partition Systems, secures the company’s long-term future. The regional newspaper Rottaler Anzeiger refers to Lindner for the first time as the largest company in the Rottal-Inn district.

In parallel, Lindner Hazardous Material Remediation begins operations as a specialist in gutting works and the proper disposal of asbestos, PCB, PCP, and similar substances.

The Fall of the Wall Opens New Markets

German reunification creates a new market for Lindner. Thanks in part to the relocation of the federal government to Berlin, the capital becomes a major centre of activity for the company. At times, up to 1,000 Lindner installers work on Berlin construction sites.

1980s

Chronicle

1990s

6

Thank You for 25 Years! The Hans Lindner Foundation Is Established

Lindner celebrates its 25th anniversary. We present our products and services across Germany in ten cities, accompanied by the Arnstorf brass band, an ox roast, and Bavarian beer – a travelling circus of sorts.

Out of gratitude for the company’s successful development, Hans establishes the non-profit Hans Lindner Stiftung as a public foundation under civil law. The foundation is dedicated to supporting people in need and promoting start-ups in the rural economic region of Lower Bavaria in order to create jobs.

As part of its activities, the Hans Lindner Foundation takes over the former district hospital in Arnstorf. The large complex is converted into the Parkwohnstift multi-generational residence, where more than 250 people spend their later years in assisted living arrangements.

Milestone Project: Hong Kong Airport

By now, around half of all contracts are in the turnkey fit-out sector. These projects demand a particularly high level of expertise and commitment from employees and ensure capacity utilisation across production, installation, and project management.

The major contract for Hong Kong International Airport Chek Lap Kok, valued at over 90 million DM, is signed. With 160,000 m² of metal ceilings, it is the largest contract in the company’s history. The smooth execution of the project fills Hans Lindner and his employees with pride – particularly given the distance of a 12-hour flight and a time difference of six to seven hours.

The quality management systems of Lindner AG and Lindner Isoliertechnik und Industrieservice GmbH are successfully certified in accordance with DIN EN ISO 9001. This underlines the group’s commitment to working transparently, safely, and at the highest level for its customers.

Fundatia Hans Lindner for Youth Development

In Satu Mare, Romania, the social foundation Fundatia Hans Lindner is established to support young people. In 1999, a further foundation follows in Kampala, Uganda, again focusing on children and young people. Hans Lindner and his family regularly spend time with the staff of the foundations at their respective locations.

Goldbach NORIT Becomes Part of Lindner

The Goldbach NORIT Group, a recognised specialist in high-quality system flooring, significantly enhances Lindner’s product portfolio and gives the family-owned company a growth boost in the midst of a construction downturn. Lindner flooring systems remain among the market leaders to this day.

1990s

Chronicle

2000s

7

A New Ambition: In-House Project Development

The groundbreaking ceremony marks the start of Business Park Sofia in Bulgaria. With this project, the Lindner Group expands its expertise to include project development. Lindner Immobilien Management EOOD now develops its own residential, office, and industrial projects nationwide, overseeing construction management, planning, sales, and marketing.

Business Park Sofia is developed on a site of 220,000 m², creating around 240,000 m² of office and commercial space for 650 companies. Following its successful completion, further projects are realised in subsequent years, including Residential Park Sofia and Residential Park Lozen.

For Society

Hans Lindner is awarded the Bavarian Order of Merit in recognition of his entrepreneurial and social commitment. Following the award of the Order of Merit of the Federal Republic of Germany (Cross of Merit on Ribbon in 1993 and First Class in 1998), this honour once again underlines Hans Lindner’s role as a role model for entrepreneurs and socially engaged individuals in Bavaria.

Certified Acoustic Laboratories in Arnstorf

At the Arnstorf headquarters – now comprising more than 100,000 m² of office and production space — Lindner establishes its own acoustic laboratories. Project-specific adaptation of in-house system products is a core Lindner competency. TÜV-certified laboratories significantly shorten product development times and enable the testing of customised solutions even under considerable time pressure.

To preserve a historic landmark, Lindner AG acquires the former moated castle of Mariakirchen from the 16th century in the neighbouring village and begins a comprehensive restoration. Among other uses, the site is transformed into a picturesque training centre for Lindner employees and external companies.

A Favourite Passion: Brewing Beer

The innkeeper’s son fulfils a lifelong dream: Hans Lindner opens his own brewery next to Mariakirchen Castle, Schlossbräu Mariakirchen. The former castle stables, built in 1785, now house not only the brewery but also several traditional parlours offering space for events with more than 200 guests.

Meanwhile, the internationalisation of the group continues. A new subsidiary in China strengthens Lindner’s presence in Asia. At the Taicang site, metal ceilings and partition systems have since been produced to German quality standards.

A New Production Facility for Wooden Doors

What began as aw-Türen develops into a business unit with strong future potential. As a result, construction of a modern production facility for Lindner doors begins in Ostrov, Czech Republic. Since then, colleagues there have been manufacturing wooden doors of every specification – from standard project doors to acoustic and fire-rated doors with special surfaces and custom dimensions.

Schmidlin (UK) Becomes Part of Lindner

The British facade specialist Schmidlin (UK) joins the Lindner Group, completing its full-service offering. Production of system and bespoke facades is established in Arnstorf. The acquisition also expands Lindner’s scope of work on the major project Heathrow Airport Terminal 5: Lindner is now responsible not only for interior fit-out but also for the building envelope. As a result, the contract volume at Heathrow Airport increases to approximately EUR 130 million.

Hans Lindner is named an honorary citizen of his hometown Arnstorf. Previously, in 2001, the Romanian city of Satu Mare had already awarded him honorary citizenship.

Opening of Schlossparkhotel Mariakirchen

The Lindner family opens its first hotel: Schlossparkhotel Mariakirchen, a four-star property. The listed garden pavilion of the castle, dating from 1810, serves as the reception area. In the years that follow, further hotels are developed under the brand mk | hotels, some of them featuring their own on-site breweries.

A joint venture with Depa in Dubai lays the foundation for today’s Lindner Middle East subsidiary. Following years of preparation through its supply business, Lindner successfully enters the rapidly growing market of the United Arab Emirates. Shortly thereafter, the fit-out of the Dubai Metro Red Line stations becomes the first major contract in the region.

Launch: Ship Interior Fit-Out

Lindner once again expands its interior construction portfolio. At the renowned Meyer Werft, the first projects commence for the high-quality interior fit-out of cruise ships.

A Green Milestone: Deutsche Bank, Frankfurt

Since its founding, Lindner has focused on minimising energy and resource consumption as well as impacts on people and nature. In the 2000s, the growing market for building certifications and increasing product-level requirements open up further opportunities for sustainable innovation – across the entire value chain, from development to handover.

The refurbishment of the Deutsche Bank office towers in Frankfurt, certified to LEED Platinum and DGNB Gold, becomes a benchmark project for Lindner’s Green Building activities worldwide.

2000s

Chronicle

2010s

8

Reorganisation: Lindner Group KG

Lindner Group KG becomes the new umbrella organisation for all business divisions. What began as Akustikbau Lindner GmbH has grown into a large family-owned company with more than 6,000 employees. Today, Lindner is active on around 1,500 construction sites worldwide every single day.

Prater Joins the Group

The facade and roofing specialist Prater Ltd, headquartered in London, becomes part of the Lindner Group. As a family business with a 60-year success story, Prater is an ideal fit for the group. Its core competencies significantly strengthen Lindner’s service portfolio on the British market, where Lindner can now offer both interior fit-out and complete building envelope solutions.

Also newly added to the Lindner Group is the scaffolding business. As a subsidiary of Lindner Isoliertechnik und Industrieservice GmbH, it enhances the group’s turnkey offering for industrial projects, traditional building construction, and even specialised interior fit-out solutions.

Largest Supply Contract to Date: The Holy Mosque

The development, manufacture, and delivery of bespoke metal ceilings for the Masjid al-Haram in Mecca is not only a milestone for Lindner’s Middle East business, but also the largest supply contract in the company’s history.

Half a Century Later: 50 Years of Lindner

In 2015, Lindner celebrates its 50th anniversary with a major event and a commemorative publication that journeys through the company’s past – from its dynamic beginnings and key project milestones to possible future perspectives. Long-serving employees also share their experiences in the anniversary book, bringing the company’s history vividly to life.

Agriculture and Forestry – Good Products, a Good Life

The new Agriculture and Forestry division represents a consistent continuation of Lindner’s commitment to a world worth living in for the long term. With a strong focus on ecological and sustainable land management – such as species-appropriate grazing and the complete avoidance of animal transport – high-quality organic food products are produced both for internal use and for external distribution under the Land.Luft brand.

Just three years later, in 2019, the division expands to include a winery in southern Burgenland, Austria. Since then, organically certified Groszer wines have been produced there – with passion, care, and a deep respect for nature.

Striking Dome Structure for Expo Astana

As part of Expo 2017 Astana, Lindner Steel & Glass develops, manufactures, and installs a glass sphere structure measuring 93 metres in height and 80 metres in diameter, in close cooperation with Lindner Middle East. The so-called Kazakhstan Pavilion is, at the time, the largest enclosed glass sphere in the world and remains a landmark of the World Expo to this day.

25 Years of Lindner Lighting Factory

Following many years of close collaboration, IWS Lichttechnik becomes part of the Lindner Group in 2014 – after more than 25 years of partnership. The lighting manufacturer from Mettenbach near Landshut has been producing customised luminaires for Lindner since its founding in 1993.

Through the merger, Lindner SE | Leuchtenfabrik is now able to deliver even larger and more complex projects – ranging from minimalist system luminaires for cleanrooms to project-specific statement pieces for office environments. The entire process is covered in-house, from sales and planning to production and installation.

A partnership with Ambright GmbH, established in 2019, further complements Lindner’s expertise in lighting and luminaires.

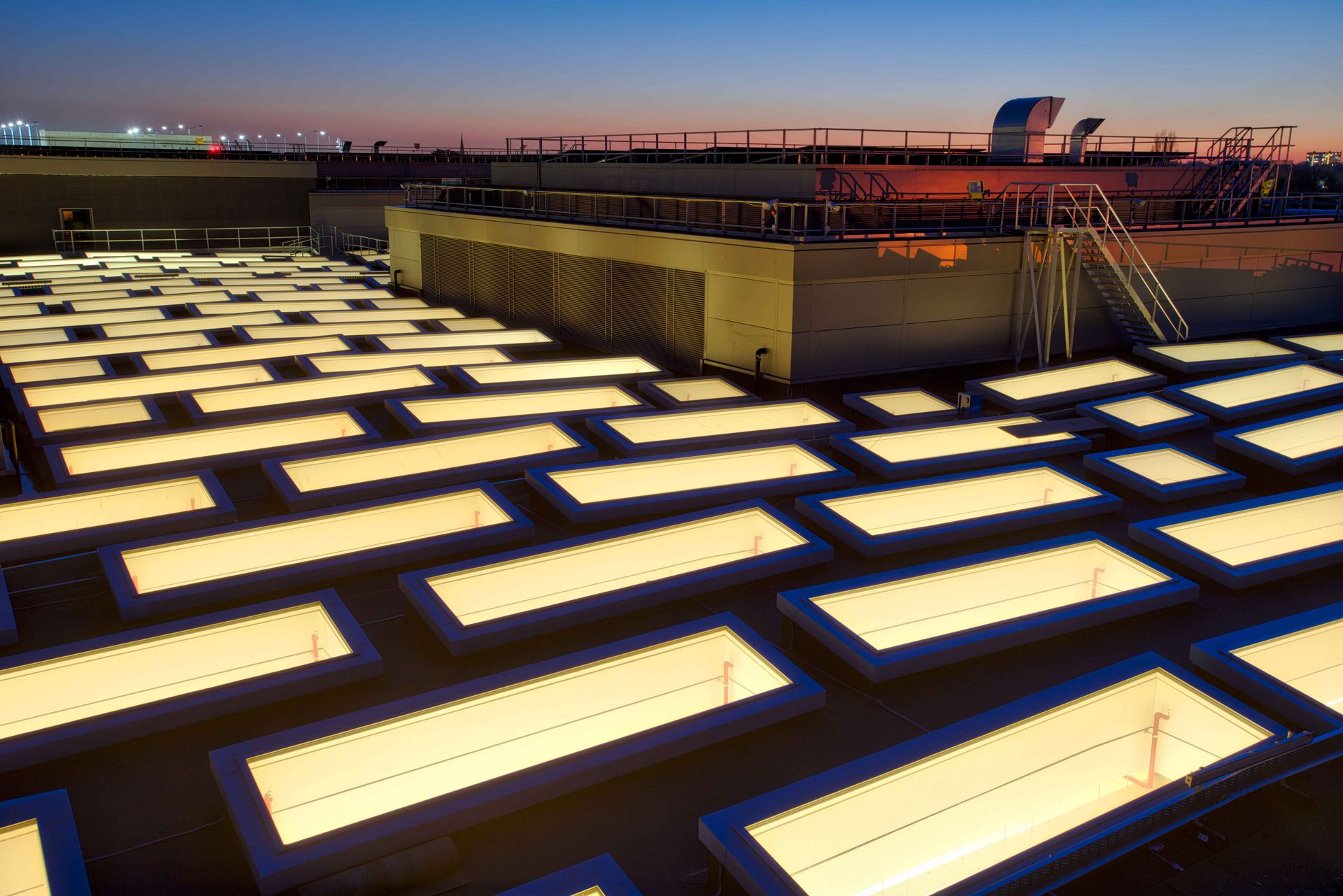

Satisfied Customers = Repeat Business

For many years, the Lindner Group has cultivated long-term relationships with its clients – because reliable delivery and consistently high-quality execution create lasting trust. This is exemplified by Fraport AG: What began as a general contractor assignment for interior fit-out works around Pier G at Frankfurt Airport has led to numerous follow-up contracts, including projects for a VIP lounge, check-in hall, and many more areas.

2010s

Chronicle

2020s

9

Together as One Big Family

Lindner AG becomes Lindner SE. With the change of legal form, Lindner’s values and vision can now be lived even more clearly in everyday working life. The new corporate structure stands for diversity, promotes a partnership-based and self-responsible leadership model, and creates ideal conditions for continuous development. At the same time, Lindner remains firmly committed to principles that also define many families – cohesion, trust, and reliability.

Highest Quality – Made in Germany

Through substantial investments, Lindner sets forward-looking benchmarks at its German sites. In Arnstorf, for example, new office spaces and a two-storey production hall have been created. The latter combines metal processing and powder coating at a single location, enabling the use of state-of-the-art technologies and energy-efficient production processes.

Investment continues at the Lower Franconian site in Dettelbach as well. Thanks to cutting-edge production facilities, gypsum fibre waste can now be processed and reused on site.

Always One Step Ahead: Advancing Digitalisation in Construction

Lindner’s answer to Construction 4.0? Proprietary tools and applications developed by its in-house digital team and IT department.

With BIM, digital planning tools, a platform for risk assessment, and much more, Lindner not only simplifies everyday work for its own employees but also enhances safety, speed, and convenience across the construction sector. These digital solutions are also made available to the wider market, allowing Lindner to share its expertise with the industry.

This innovative strength was recognised in 2022, among other honours, with the German Construction Award in the category Digitalisation, recognising the most innovative companies in the construction industry.

The Future of Construction Is Circular

Lindner closes the sustainability loop and, in 2023, puts the principles of the circular economy into practice within the construction sector. One example is the LinLoop business models, which allow system products for floors, ceilings, and walls to be rented or purchased with a return agreement – simply and flexibly.

Further sustainability highlights in the Lindner portfolio include refurbished hollow and raised floor systems, as well as numerous products certified Cradle to Cradle Certified® Silver and Gold.

IPA: Working in an Alliance

The year 2024 marks the breakthrough of Integrated Project Delivery (IPD/IPA). Lindner has been committed to this forward-looking model since 2022, promoting transparency and collaboration through multi-party agreements involving all project stakeholders – from the client to the executing trades.

With the Alliance 3 Schools Bremerhaven, the first German IPA project in public-sector building construction is successfully realised – representing a milestone for the industry.

60 Years of Lindner

In 2025, Lindner looks back on 60 years of entrepreneurial success and continuous growth. Since its founding, the company has established itself not only as a pioneer in the construction industry, but also as an innovative partner for demanding projects worldwide.

To mark the anniversary, Lindner thanks its employees with an extraordinary gesture in recognition of 60 years of commitment: 60 colleagues are sent on discovery journeys around the globe – to places where landmark projects have been realised, where Lindner subsidiaries operate, or where the Hans Lindner Stiftung is actively engaged.

2020s