With the expansion of Oslo Airport and the addition of the new Pier North terminal, Norway’s largest airport has significantly increased its passenger capacity. The new terminal section, extending 300 meters in length, adds eleven new gates and offers expanded areas for retail, dining, and passenger services. As a result, the airport can now accommodate approximately 30 million passengers annually, making it a key aviation hub in Scandinavia.

A defining architectural element of Pier North is a group of five freeform pavilions, developed, planned, and installed by Lindner, in close collaboration with the client Avinor and the architects at Nordic – Office of Architecture. These organically shaped structures were built during ongoing airport operations and are fully integrated into the terminal’s design.

To reduce construction weight and simplify logistics, Lindner proposed replacing the originally planned steel framework with a glued laminated timber (glulam) structure. The entire load-bearing system was digitally designed as a ribbed frame using 3D modeling software, resulting in more than 10,000 uniquely milled wooden components, each precisely numbered for efficient on-site assembly.

The pavilion’s exterior was formed using multiple layers of flexible gypsum plasterboards, ensuring fire resistance and the desired curvature. A mineral lime plaster finish, custom-colored in collaboration with the architects, adds visual depth and durability to the outer surface.

The interiors of the pavilions feature approximately 8,000 triangular metal panels, each individually designed to fit the complex geometry of the structures. These custom acoustic panels offer both sound control and aesthetic consistency. A project-specific substructure was developed to support the design and ensure seamless installation.

The pavilions are currently home to a duty-free shop, bookstore, bank branch, bakery, and fashion boutique. Inspired by Nordic rock formations, their organic shape creates a distinctive visual identity while blending harmoniously into the overall airport architecture.

The entire planning process was carried out using Building Information Modeling (BIM), a digital methodology that enables fully integrated 3D architectural and construction planning. BIM allowed Lindner to simulate construction phases, identify clashes early, and coordinate all trades effectively. This digital workflow helped meet critical project deadlines while ensuring top quality across all phases.

Thanks to BIM, stakeholders were able to visualize detailed design elements, perform real-time feasibility assessments, and maintain clear, continuous communication. The result was a seamless construction process, efficient material usage, and thorough documentation for long-term facility management.

In addition to the pavilions, Lindner delivered a wide range of technical interior solutions throughout the new terminal section. These include approximately 18,000 m² of custom-designed, diamond-shaped ceiling and wall claddings, as well as 2,000 m² of expanded metal ceilings and 7,000 m² of lay-in ceilings in central public areas.

A key technical feature is the FLOOR and more® power comfort raised floor system, covering 20,000 m² in total. This robust flooring solution integrates underfloor heating and cooling, enabling energy-efficient climate control in high-traffic airport environments. Designed for maximum load-bearing capacity, the system meets both functional and sustainability criteria. Installation was completed by Lindner’s local partner, Sana Bygg AS.

Project: Oslo Airport, Terminal 2

Building Type: Airports, Building certification, Others, Transportation Structures

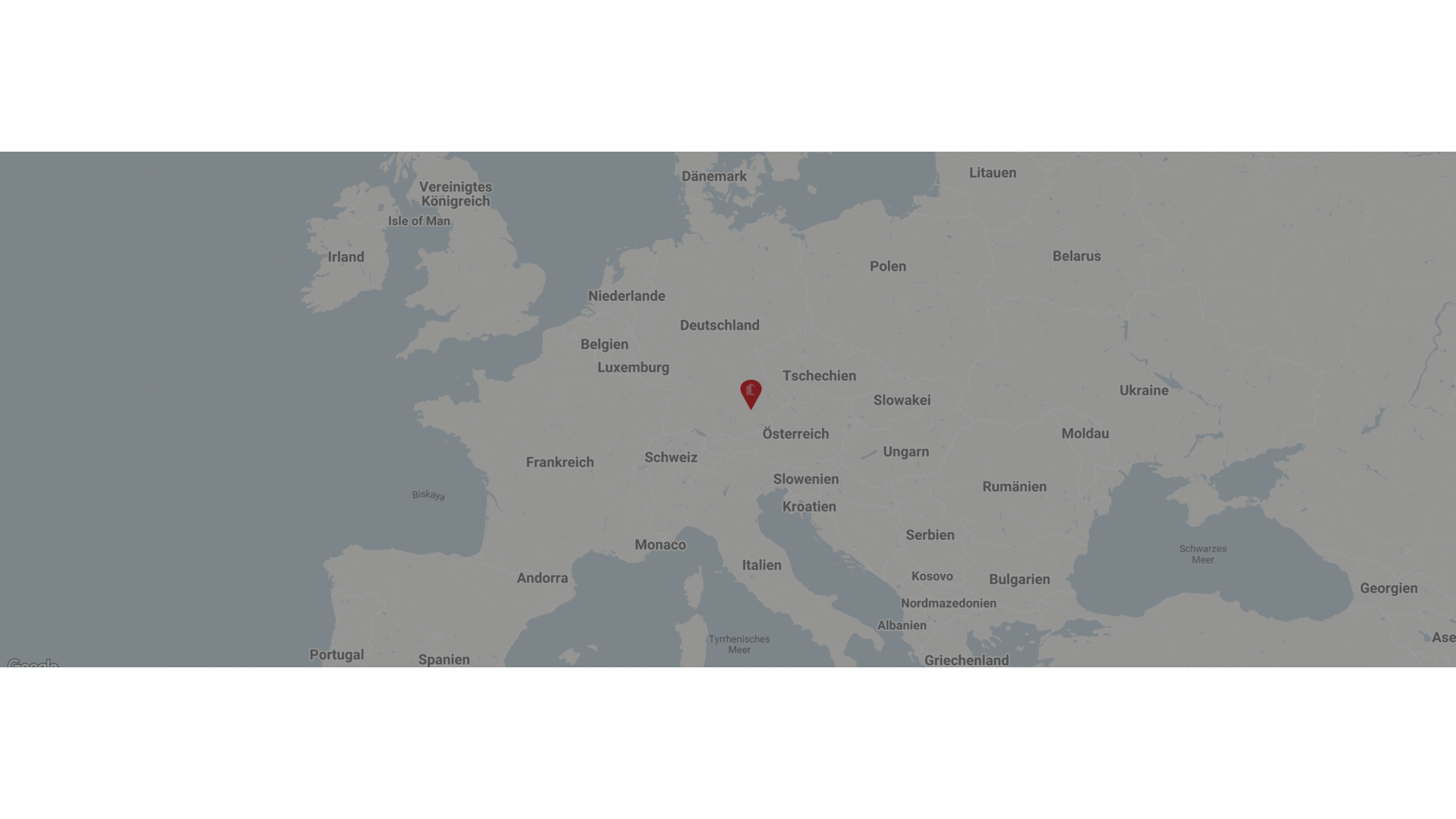

Address: Edvard Munchs veg

Zip/City: 2061 Gardermoen

Country: Norway

Completion: 2017

Company: Lindner SE I International Projects Contracting, Lindner Scandinavia AB (Exterior)

Gebäudezertifizierung: BREEAM

Architect: Nordic

Client: OSL Oslo

Dry construction works