In Nassereith, Tyrol, a state-of-the-art operational and production facility with a gross floor area of around 8,000 m² was constructed for the leading Tyrolean technology company SWACRIT systems. The new building provides the foundation to meet the growing global demand for high-tech products in the fields of semiconductor and vacuum technology.

The planning was carried out by the architectural firm ATP. The Lindner SE | Cleanroom Technology division was responsible for the complete technical design and implementation of the cleanrooms – from conceptual planning to structural design of walls, systems, and ventilation, through to detailed execution planning. Particular focus was placed on particle reduction, keeping harmful substances away that could affect later production processes, and maintaining a constant temperature with only ±0.1 K deviation.

Two different cleanrooms were implemented: an ISO 6 room of approximately 1,500 m², which can optionally be upgraded to ISO 5, and an ISO 8 room of around 200 m². Mobile Cleanroom workstations with integrated FFUs and perforated work surfaces additionally provide particle safety and flexibility.

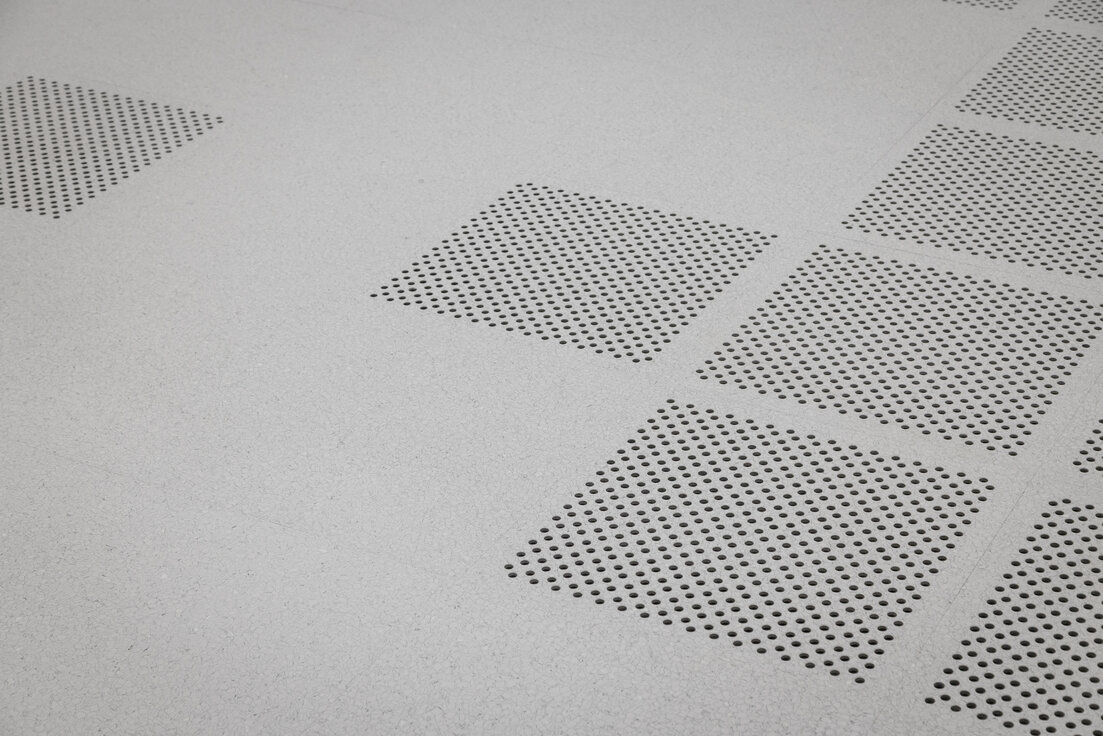

The cleanrooms feature the PRODATA raised floor and the ALUVENT perforated raised floor over more than 1,000 m². These systems offer maximum load-bearing capacity, perfectly level surfaces, and safe integration of supply lines. Room division was realised using the Multiclean LVT cleanroom wall system, which meets all DIN EN ISO 14644 requirements and clearly separates different process areas.

Various Lindner door systems were installed to provide secure access. Swing MPH cleanroom doors combine a flush design with high durability and easy cleaning. They are complemented by fire doors and the Inline 2 control system, which enables intelligent airlock logic. Personnel airlocks are equipped with air barrier systems to reliably remove particles from staff.

In the cleanroom area, the Line 100S Type 2 cleanroom ceiling was installed over an area of around 1,600 m². It provides stability and allows the integration of technical elements. Air cleanliness is ensured by integrated Fan Filter Units and two FFUSD systems, which maintain a uniform, low-particle airflow. Numerous RR o cleanroom lights provide even, glare-free illumination of workstations.

In the workshop, the Clip K3 ceiling system was chosen. This Clip-In/Fold-Down system allows individual panels to be folded towards the room side, greatly facilitating maintenance and cleaning. Integrated lights ensure energy-efficient and standards-compliant lighting.

Special attention was paid to resource-efficient construction. By recovering heat from production processes and using geothermal energy, the facility operates entirely without fossil fuels. Photovoltaic systems on the roof and parking areas supply the production with independent, self-generated electricity. Greened outdoor areas, reduced surface sealing, and the integration of wooden ceilings contribute to sustainable practices and harmonise with the Alpine surroundings.

Project: Cleanroom Expansion for New SWACRIT Site in Nassereith

Building Type: Office Buildings, Factories and Production Facilities, Clean rooms (electronics and semiconductor technology), Industrial and commercial construction

Zip/City: 6465 Nassereith

Country: Austria

Completion: from 2024 to 2025

Company: Lindner SE | Clean Rooms

Architect: ATP architekten ingenieure

Client: SWACRIT systems GmbH

Clean Room

Hinged doors

16 Pcs.

Sliding doors

2 Pcs.

Door interlocking systems

9 Pcs.

Steel grid systems

1620 sqm

Clip-in cassette systems

185 sqm

144 Pcs.

17 Pcs.

178 Pcs.

2 Pcs.